Transfer Path Analysis

Road Noise

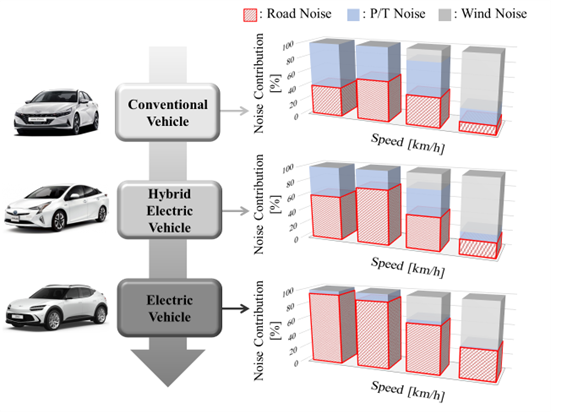

In recent years, the automobile industry trend is rapidly changing from the internal combustion engine to electric power motor. Conventionally, the noise generated from the internal combustion engine mostly masked other noises, so the interior noise was reduced by focusing on the powertrain noise. In the case of electric vehicles, problems such as road noise, brake noise, and hydraulic system noise are emerging. In particular, the road noise contribution of electric vehicles accounts for the largest portion at 40 %. In general, road noise with a frequency below 500 Hz is considered as structure-borne noise is caused by the irregular interactions between the wheels of the travelling vehicle and the road surface. The noise is transmitted from the wheel to the interior sound pressure level via the suspension, which acts as a transfer path. Therefore, modifying the transfer path (i.e., suspension) can lead to an improvement in the vibro-acoustic performance of the vehicle with respect to road noise.

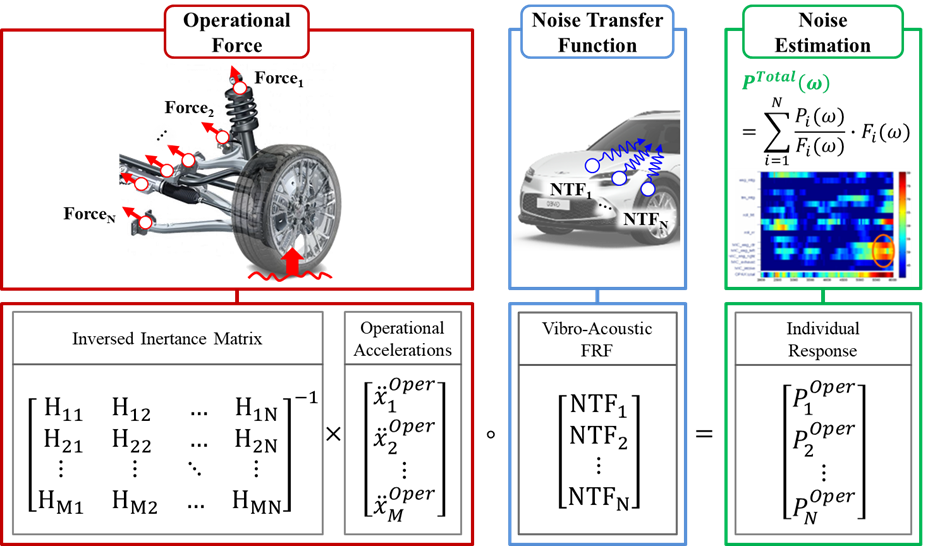

Transfer Path Analysis

Transfer path analysis (TPA) is the process of determining the priorities for a variety of possible paths from noise and vibration sources to an output response. To reduce responses such as noise, it is essential to determine the efficient transfer paths in terms of the transmission and isolation of the noise. This analysis is mainly employed to evaluate the noise, vibration and harshness (NVH) characteristics during vehicle design. In particular, the structure-borne road noise of a vehicle is attributed to the road-tire interactions, which excite the suspension linkages, and in turn, the other vehicle parts. Consequently, these parts generate interior noise. Considering the development cycle of a vehicle with numerous parts, it is necessary to conduct TPA at an early stage, especially for the improvement of the vibro-acoustic performance. Moreover, by the selection of a critical path for each individual frequency band, the time and energy required for NVH performance improvements can be significantly reduced.